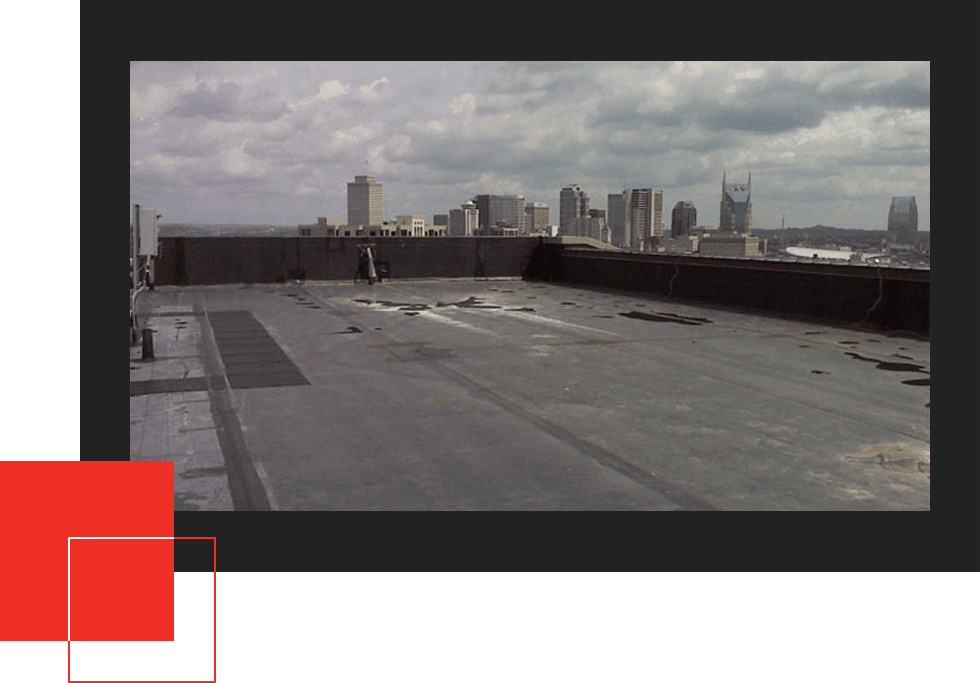

Ballasted EPDM

The Ballasted EPDM Roof System utilizes large EPDM sheets held in place by smooth river stone or pavers. This system is extremely versatile and available in several different variations. When stone ballast is used, this system is the most economical. The smooth stones used in this system offer an aesthetically pleasing surface appearance. The weight of the basic Ballasted Roof system is 12-14 pounds per square foot. Most Factory Mutual and Underwriters Laboratory recommendations can be met with this system. All EPDM membranes can be used in this system, which includes 45 mil and 60 mil non-reinforced and 45 mil and 60 mil reinforced, but the 45 mil non-reinforced is the most commonly used. 5, 10, 15, or 20-year watertight warranties are available.

Fully Adhered EPDM

With the Fully Adhered EPDM Roof System, the EPDM sheets have fully adhered to the substrate with bonding adhesive. This system is extremely versatile and can be installed on steep slopes. This system also adapts itself very well to curved roof surfaces. This system is lightweight -- less than 2 pounds per square foot with most applications. This system is easily repaired. All Factory Mutual and Underwriters Laboratory recommendations can be met with this system. All EPDM membranes can be used in this system, which includes 45 mil and 60 mil non-reinforced and 45 mil and 60 mil reinforced, but the 60 mil non-reinforced is the most commonly used. A white EPDM is also available that offers heat reflectivity. 5, 10, 15, or 20-year watertight warranties are available. (5 and 10-year watertight warranties available with a white membrane.)

Mechanically Fastened EPDM

With the Mechanically Fastened EPDM Roofing System, the EPDM sheets are fastened to the substrate with mechanical fasteners. This system is extremely versatile and can be installed on steep slopes. This system also adapts itself very well to curved roof surfaces. This system is lightweight -- less than 2 pounds per square foot with most applications. This system is easily repaired. All Factory Mutual and Underwriters Laboratory Ratings can be met when using a reinforced membrane with this system. All EPDM membranes can be used in this system which includes 45 mil and 60 mil non-reinforced and 45 mil and 60 mil reinforced. 5, 10, or 15-year watertight warranties are available.

Metal Retrofit EPDM

For installation over failing metal roofs. The EPDM roof sheets are fastened to the existing roof support structure with specially designed roof fasteners. This system is less costly than a complete replacement with a new metal roof. Plus, there is no downtime for the building occupants while this roof is installed. Weighs less than 3 pounds per square foot. The pans of the metal roof are filled in with roof insulation; then, the entire roof is overlaid with roof insulation. The addition of this roof insulation results in energy saving, helping the building owner pay the roof cost. All Factory Mutual and Underwriters Laboratory Ratings can be met with this system. 45 mil and 60 mil reinforced membranes are used in this system. 5, 10, or 15-year watertight warranties are available.

Ballasted Heat Welded Thermoplastic

The Ballasted Heat Welded Thermoplastic Roof System utilizes heat-welded sheets held in place by smooth river stone or pavers. This system is extremely versatile and available in several different variations. When stone ballast is used, this system is the most economical of the heat welded systems. The smooth stones used in this system offer an aesthetically pleasing surface appearance. The weight of the basic Ballasted Roof System is 12-14 pounds per square foot. Most Factory Mutual and Underwriters Laboratories' recommendations can be met with this system. Either the 45 mil or 60 mil membranes can be used in this system. 5, 10, or 15-year watertight warranties are available. The heat-welded systems that include PVC and TPO membranes are somewhat chemical resistant and stand up well to animal fats.

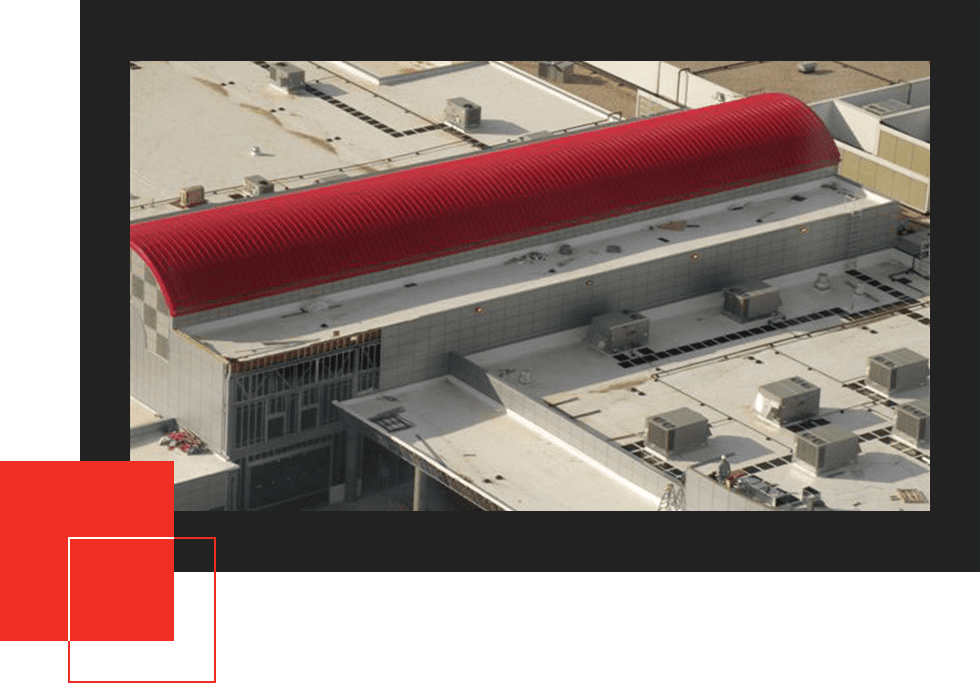

Fully Adhered Heat Welded Thermoplastic

With the Fully Adhered Heat Welded Thermoplastic Roof System, the heat welded sheets have fully adhered to the substrate with bonding adhesive. This system is extremely versatile and can be installed on very steep slopes. This system also adapts itself very well to curved roof surfaces. This system is very lightweight -- less than 2 pounds per square foot with most applications. This system is easily repaired. All Factory Mutual and Underwriters Laboratory Ratings can be met with this system by following their recommendations. Either the 45 mil or 60 mil membranes can be used in this system. The heat-welded membrane is available in two colors: white, which offers heat reflectivity, and black. The heat-welded systems that include PVC and TPO membranes are somewhat chemical resistant and stand up well to animal fats. 5, 10, or 15-year watertight warranties are available.

Mechanically Fastened Heat Welded Thermoplastic

With the Mechanically Fastened Heat Welded Thermoplastic Roofing System, the heat welded sheets are fastened to the substrate with a type of mechanical fasteners. This system is extremely versatile and can be installed on steep slopes. This system also adapts itself very well to curved roof surfaces. This system is very lightweight -- less than 2 pounds per square foot with most applications. This system is easily repaired. All Factory Mutual and Underwriters Laboratory Ratings can be met with this system by following their recommendations. All heat welded membranes can be used in this system, which includes 45 mil and 60 mil reinforced. The heat-welded membrane is available in two colors: white, which offers heat reflectivity, and black. The heat-welded systems that include PVC and TPO membranes are somewhat chemical resistant and stand up well to animal fats. 5, 10, or 15-year watertight warranties are available.

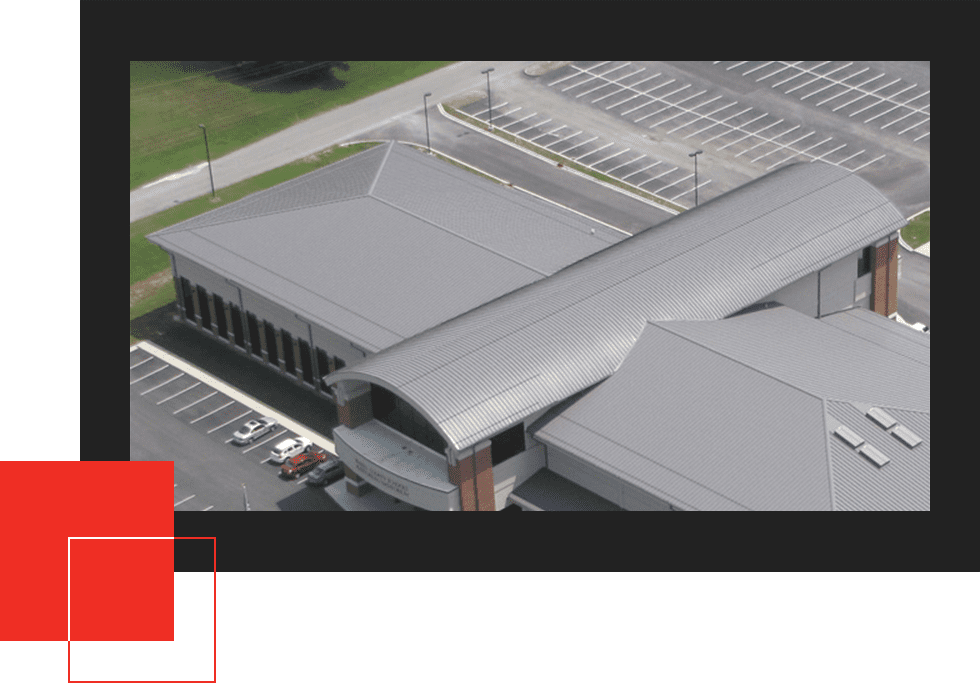

Metal Roofing

There are several different varieties of metal roofing; the "standing seam" or "architectural" panels are the elite types of metal roofing that can be installed on commercial buildings. This type of system is made up of a series of panel clips that are fastened down to one leg of the metal panel itself. This clip is then covered by another panel which is "locked" onto the panel already fastened in place. This type of system allows the use of metal panels with hidden fasteners, so they will last for years to come. These systems can be obtained in 26 gauge but are generally 24 gauge materials with a variety of finishes, from galvanized or copper to a painted Kynar finish with a 20 year no fade warranty.

Our customers are our top priority

Please take a moment to browse our site and feel free to contact us with any questions you may have.